Specifiers Guide to Nordic Softwoods for Joinery 2024

Specifiers Guide to Nordic Softwoods for Joinery 2024

Introduction:

Rather than selecting only traditional native and imported hardwood species, specifiers are increasingly choosing technically advanced timber products that are certified and sourced responsibly. This is taking place against the backdrop of a declining supply of traditional Australian native hardwoods. Due to environmental (i.e., illegal logging) legislation, specifiers are also starting to steer clear of potentially sensitive imported tropical hardwoods.

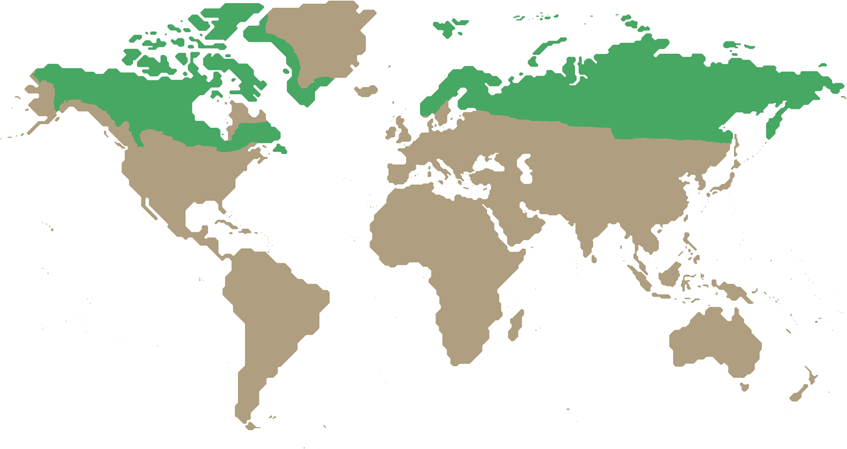

Plantation-grown short rotation hardwoods are not the solution, as they are not typically suitable for solid wood applications. While short-rotation hardwoods offer benefits such as faster growth and increased sustainability, they also come with some downsides for architectural purposes. One notable drawback is that these hardwoods may have lower dimensional stability and durability compared to their slower-growing counterparts. Nordic softwood has gained recognition and popularity for its availability and accessibility, exceptional quality, sustainability, and overall superiority compared to other types of timber. The cold climate and slow growth of trees in the Taiga-Boreal forests (see Figure 1) result in robust and durable wood. Additionally, Nordic countries have an established tradition of sustainable forest management, ensuring the preservation and regeneration of forests for future generations.

With a history dating back to the 1830s, Nordic wood has a long heritage in Australian homes since European settlement. Norwegian sawn and dressed ‘Baltic’ wood was delivered to Australian ports via sailing vessels until the early 1900s. Before the Suez Canal opened, ships sailed via the Cape of Good Hope, with sailing times varying up to four months, but now timber is typically containerised for faster transportation.

In this whitepaper, we provide a background on Nordic forestry and the relevant factors to consider when specifying Nordic softwood.

Understanding Nordic forestry Durability

Background

Sweden, Norway, and Finland are home to some of Europe’s most abundant forests, collectively possessing over 61 million hectares of forest land out of Europe’s total of 211 million hectares. Denmark’s contribution of approximately 625,000 hectares also contributes to the Nordic region’s 20% share of Europe’s total wood stock. On average, individuals in Sweden, Norway, and Finland have access to around three hectares of forest land each.1

Any concern that European forest growth has stagnated is unfounded. From 2005 to 2020, the forest area in Europe expanded by 58,390 square kilometers. This translates to the addition of forest equivalent to the size of 1,500 football pitches each day.2

The Nordic region plays a significant role in this remarkable upward trend. For example, in Finland and Sweden, laws mandate the replanting of harvested forests, with three to four new seedlings planted for every mature tree harvested. Forests serve as a renewable asset that is essential to Finland’s prosperity and societal well-being, with nearly 60% of Finnish forests privately owned.3

Private forest ownership encompasses a variety of traditional and non-industrial entities, such as families, farms, rural commons, churches, and estates. Additionally, industrial private ownership includes companies in the forest industry involved in pulp and paper production, among other activities.

Biodiversity

In Nordic forests, both industry and forest owners prioritise preserving biodiversity by focusing on planting only native tree species. This approach is crucial for maintaining the balance and health of local ecosystems.

In sustainable forestry, such as those in the Nordic region, it is essential to guarantee the regeneration of new forests following clearcutting operations. One common practice involves leaving retention tree groups within the forest, which ensures a diverse range of tree ages that eventually contribute to the natural cycle of decay and regeneration. By preserving decaying wood and old trees, which may be important to local species, retention trees play a crucial role in promoting biodiversity. Another practice involves identifying and designating specific areas for conservation purposes. This includes creating buffer zones around water bodies, protecting steep slopes, preserving trees with hollows that serve as wildlife habitats, and safeguarding other crucial environmental features.

Certification

In global markets, there is a demand for wood and wood- based products sourced from certified forests that are managed in a responsible manner. The two primary global organisations responsible for forest certification are the Programme for the Endorsement of Forest Certification (PEFC) and the Forest Stewardship Council (FSC). Both PEFC and FSC are internationally recognised networks that certify forests according to regional and national standards, ensuring they meet the criteria for sustainable forest management.

Finland, Sweden and Norway are in the top ten countries when it comes to PEFC certification.4 As of Dec 31, 2023, approximately 19,349,469 hectares of forest in Finland are PEFC-certified, amounting to 86.3% of national coverage.5 Sweden has 16,405,488 hectares of certified forest (86.6% national coverage), whereas Norway has 7,351,500 (60.4% national coverage).6

Responsible companies

The Nordic region is home to leading manufacturers and suppliers that are committed to supporting the use of wood in a responsible and environmentally sensitive manner. Notable companies in this regard include:

- LuvianSaha Oy; Versowood;

- PölkkyOy; Lunawood;

- WestasGroup; Stora Enso; and

- Raitwood; Metsä Wood.

Specifying Nordic softwood

Species

Nordic softwood species include Nordic Redwood (Scots Pine) Pinus Sylvestris and Nordic Whitewood (Nordic Spruce) Picea Abies. These species are generically known in Australia as Baltic. Nordic Whitewood typically exhibits a creamy white hue with subtle hints of yellow and/or red. Its fine, even texture and straight grain contribute to its consistent appearance. Nordic Redwood trees feature noticeable yellowish-white sapwood and reddish heartwood, with a clear boundary between the two. Slow growing cold climate varieties, exhibit a fine grain texture.

Material properties

European joinery and moulding manufacturers favor Nordic softwood due to its exceptional machining properties, which allow for high quality finishes in joinery and moulding components. This timber boasts outstanding paint holding, nailing, and gluing capabilities while also naturally accommodating weather-induced movements.

Nordic joinery grade timber is characterised by its small, sound knots and is graded to ensure the best face appearance. Other product types include Side Board, featuring very few knots, as well as ‘continuous-grain’ laminated and ‘thermally-modified’ options.

Nordic softwood sourced from the Sub-Arctic regions, where growth rates are exceptionally slow, results in timber with a super-fine grain and increased density, contributing to its strength and durability. While Nordic softwood is naturally durable and resistant to decay, it can also be treated with various impregnation methods to make it suitable for challenging environments.

Applications for Nordic softwood

Enhanced durability and stability make Nordic softwood suitable for both indoor and outdoor uses across various settings, spanning from residential homes to heavily frequented public areas. It is particularly well suited for environments that typically pose challenges for untreated wood, including exterior cladding, siding, and decking, along with being used for garden and sauna timbers. Moreover, it finds application in interior spaces such as floors, paneling, ceilings, and wet areas, as well as in joinery for windows, doors, and mouldings.

Durability and treatments

To provide enhanced durability and strength, Nordic softwoods are available in natural form or with additional treatments such as Thermal Modification or High-Pressure Alkaline Copper Quaternary (ACQ) or Chromated Copper Arsenate (CCA) full cell impregnation for weather-exposed and in ground contact. Flame-retardant coatings may be used in higher-risk bushfire zones.

AS/NZS 1604.1:2021 requires that any product purporting to be treated with preservatives adhere to the branding requirements outlined in the standard. A crucial component of this branding is the Hazard Class classification, which communicates the service conditions the product will encounter and the necessary level of treatment or protection required for the wood.

Finishing

It is important to take precautions to protect sapwood that is exposed to wetting. For optimal durability, with the exception of thermally modified wood that can be used without a coating, it is advised to apply a base primer followed by three coats of high-quality oil-based paint to exterior surfaces. When it comes to interior applications, any high-quality paint or stain can be chosen to complement your design preferences.

Pre coated Nordic softwood options can be specified for challenging exterior applications. These products come with coatings of eco-friendly water-based paints, rigorously tested to ensure resilience against weather conditions.

Maintenance

To preserve your investment, repainting is recommended every five to six years, adjusting the frequency based on factors like the exterior conditions and local environment. Continuous exposure to direct sunlight gradually deteriorates the paint finish.

Fire protection

Interior and exterior Nordic softwood products can be treated with commercially accessible flame retardant coatings. In regions susceptible to bushfires, Nordic softwood is appropriate for construction in sites assessed to BAL-19 in accordance with AS 3959: 2018. For areas with higher bushfire ratings, Nordic softwood can still be specified with the application of flame-retardant coatings specified in AS 3959, ensuring compliance and safety across different timber types (depending on the species).

Nordic softwood sourced from the Sub-Arctic regions, where growth rates are exceptionally slow, results in timber with a super fine grain and heightened density, contributing to its strength and durability.

Architectural benefits of Nordic softwood

Availability and quality

The accessibility of Nordic softwood makes it a promising option for Australian joineries and manufacturers, especially as Australian states are gradually closing down their native timber industries. Aligned with the global timber supply trends in Europe, Nordic softwood offers a sustainable, high quality and steadily increasing source of timber.

Interchangeable with native and tropical hardwoods

In many applications, Nordic softwood is interchangeable with both native and tropical hardwoods. Products can be treated to H3 for weather-exposed applications, which provides protection for above-ground settings and places that are exposed to periodic wetting. However, there are distinctions in durability, particularly in high-wear areas. For instance, flooring and door sills may show marks if subjected to heavy impact, highlighting the need for careful consideration of usage and maintenance.

Light-coloured appearance with small intergrown knots

Nordic softwood distinguishes itself from other woods with its prominent knots and exceptional grains. Its light color and performance qualities render it particularly receptive to a range of light, dark and bright finishes. These qualities make Nordic softwood an attractive option for interior design applications, including ceilings, feature walls, and flooring, where it adds a unique charm and aesthetic appeal to any space.

Ideal for lightweight construction

Nordic softwood stands out for its high strength-to-weight ratios, surpassing both hardwoods and Radiata Pine. This characteristic, coupled with its cost effectiveness, has madeit a preferred choice among fabricators and contractors. Its enhanced stability significantly reduces the occurrence of warping or cupping, leading to better yield and less waste during fabrication. Moreover, its lightweight nature inherently contributes to less resource-intensive construction

Suitable moisture content for Australian conditions

Nordic softwood is seasoned solely by air to achieve a 12% moisture content that is suitable for Australian conditions. This natural drying process, also referred to as seasoning, is conducted in purpose-built facilities and allows the wood to dry without external assistance. As a result, the timber’s strength and stiffness are enhanced, while its susceptibility to breakage or warping is significantly reduced.

Sustainability and environmental credentials

Leading suppliers offer certified Nordic softwood products under schemes such as PEFC and FSC®. These certifications play a crucial role in conserving biodiversity and safeguarding the diverse habitats and ecosystems found in natural forests. LEED (Leadership in Energy and Environmental Design) is the world’s most widely used green building rating system and offers a framework for designing and constructing environmentally friendly and cost-effective buildings. Building with Nordic softwood not only meets high environmental standards but also qualifies for LEED points in various categories, such as low emission building materials and the use of rapidly renewable resources.

Moreover, Nordic Softwood offers a significant advantage in reducing carbon impact, with each cubic meter storing approximately 250 kilograms of carbon. This carbon sequestration capacity makes Nordic softwood a sustainable choice for construction projects, helping mitigate the environmental footprint associated with building materials.

Premium Nordic Softwood from Wright Forest

Wright Forest is a boutique specialist importer of premium Nordic softwoods. Nordic Redwood (Pinus Sylvestris) and Nordic Whitewood (Picea Abies), commonly known as ‘Baltic’ species, are highly favored by designers, artisans and manufacturers around the world. With Nordic Redwood being particularly sought-after and Whitewood gaining traction for high quality applications, these softwoods cater to diverse market requirements.

Incorporating these softwoods into contemporary construction and heritage restoration projects involves deploying cutting edge technologies for drying and treatments, including chemical impregnation and thermal processes to enhance durability and stability. Innovations like Thermowood, sourced from Wright Forest’s esteemed partner Lunawood®, exemplify these advancements. All sourced products adhere to stringent PEFC certification standards and Illegal logging regulations ensuring sustainable and ethical practices. Nordic softwoods boast a rich legacy dating back to the European settlement era in Australia. Spanning three centuries, these prized timbers were transported aboard sailing ships from Norway and the Baltic region to support construction and joinery endeavors. Initially used as ballast on ships returning from the United Kingdom and European ports, these timbers provided essential building materials for burgeoning Australian colonies, including sawn timber, flooring, lining board, and weatherboards.

The Wright family’s archives trace back imports of these timbers as far as 1853, highlighting a tradition that continues today as these same timbers are imported to serve joinery and moulding needs across Australia.

Aligned with the global timber supply trends in Europe, Nordic softwood offers a sustainable, high quality and steadily increasing source of timber.

References

1 Nordic Family Forestry. “Multifunctional European forests – A growing resource in responsible hands.” NFF. https://nordicforestry.org/page/nordic-family-forestry (accessed 18 April 2024).

2 Metsä Group. “Facts about Nordic forests.” Metsä Group.

https://www.metsagroup.com/globalassets/metsa-board/documents/other-documents/fact-sheets/facts-about-nordic-forests.pdf (accessed 18 April 2024).

3 Metsäteollisuus. “Facts about Finnish forests.” Metsäteollisuus. https://www.metsateollisuus.fi/newsroom/facts-about-finnish-forests (accessed 18 April 2024).

4 Programme for the Endorsement of Forest Certification. “Facts and figures.” PEFC. https://pefc.org/discover-pefc/facts-and-figures (accessed 18 April 2024).

5 Ibid.

6 Ibid.

All information provided correct as of May 2024

Sorry, the comment form is closed at this time.